Technical Parameter

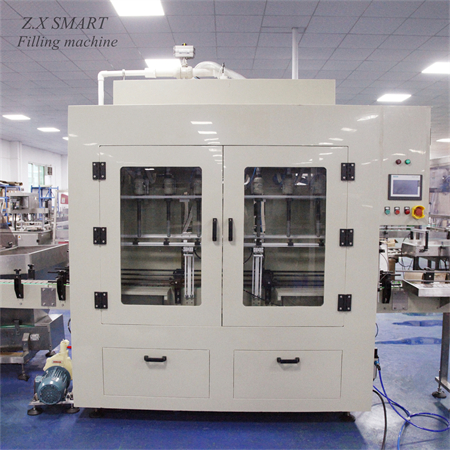

Anti corrosion piston filling machine

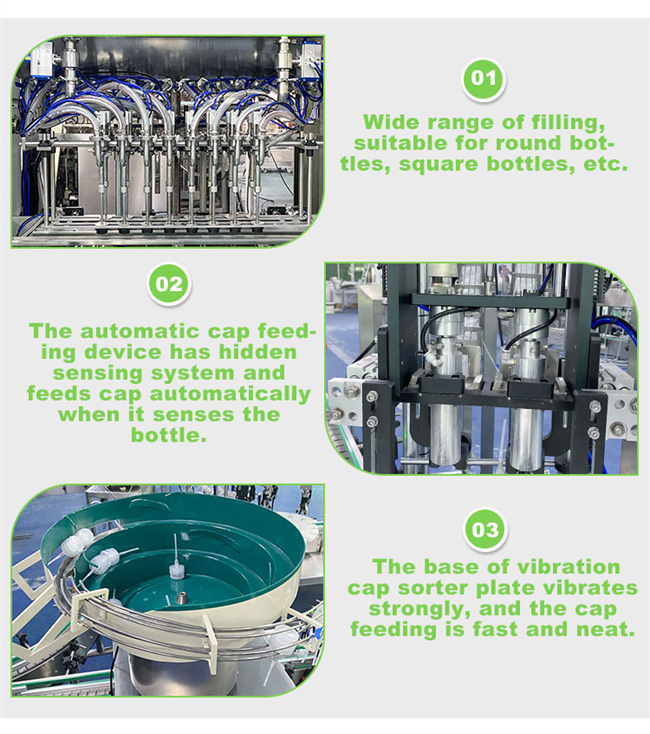

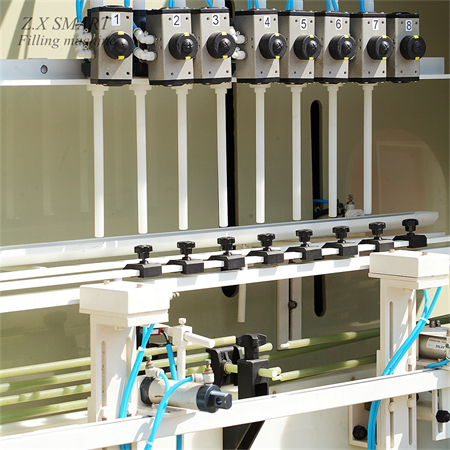

1. Number of filling heads: 6

2. Filling capacity: 100ml-1000ml

3. Filling form: servo driven piston quantitative filling

4. Filling speed: 750 bottles / hour (1000ml)

5. Filling accuracy: ± 1%

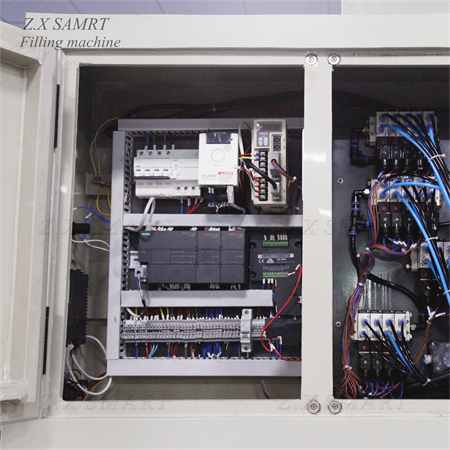

6. Program control: PLC + touch screen

7. Material: the material contact part is made of non-metallic material, the piston cylinder body is made of ceramic, and the exposed part is sprayed with Teflon; Pipeline valves are made of corrosion-resistant non-metallic materials;

8. Air pressure: 0.6-0.8mpa

9. Conveyor belt: 82mm POM chain belt, speed 0-15m / min, ground height 980mm ± 25mm

10. Conveying motor: 750W variable frequency speed regulating motor

11. Power: about 2.2kw/380v three-phase five wire

12. Chute capacity: 150L.

13. The conveyor belt inlet is equipped with a single side bottle placing workbench: 800x300mm (length x width)

Main configuration

1. PLC + HMI: Siemens

2. Cylinder and solenoid valve: AIRTAC

3. Sensor: Leuze

4. Conveyor belt motor: Yongkun

5. Conveyor belt motor frequency converter: Schneider

6. Filling drive servo motor: Schneider

7. Relay: Schneider

8. Air switch: Schneider

9. Filling nozzle lifting motor: Yongkun